Basic configuration of HZS series stationary concrete batchi

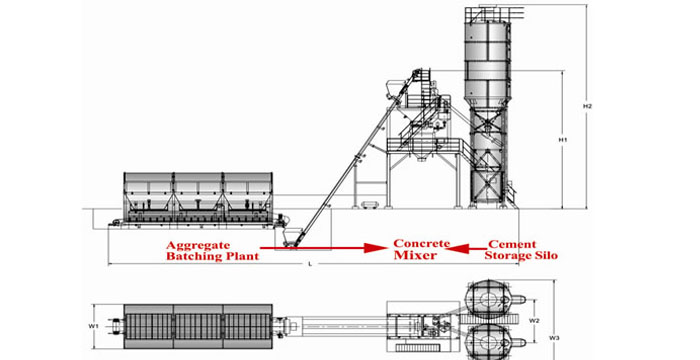

The basic configuration of HZS series stationary concrete batching plant:

The HZS series stationary concrete batching plant is mainly composed of five major systems, such as mixing host, material weighing system, material conveying system, material storage system and control system, and other ancillary facilities.

1. Mixing host

The mixing machine is divided into a forced concrete mixer and a self-propelled concrete mixer according to the stirring mode. The forced concrete mixer is the mainstream of the concrete mixing station at home and abroad. It can mix a variety of concretes such as fluidity, semi-dryness and dryness. The self-propelled mixing machine mainly mixes fluid concrete and is currently rarely used in mixing stations. The forced concrete mixer is divided into a spindle planetary concrete mixer, a single-shaft concrete mixer and a twin-shaft concrete mixer according to the structure. Among them, the twin-shaft forced concrete mixer has the best comprehensive performance.

2. Material weighing system

The material weighing system is mainly divided into three parts: aggregate weighing, powder weighing and liquid weighing. Under normal circumstances, 20m3/aggregate (sand, stone) is weighed with a rod scale, cement and fly ash with a rod scale, water and liquid admixture, and then the liquid admixture is placed in the water bucket to pre-mix. In the way of 50m3 / independent weighing of various materials, all weighing is controlled by electronic scale and microcomputer. The weighing accuracy of aggregates is 2%, and the weighing accuracy of cement, powder, water and admixtures all reach 1%.

3. Material conveying system

Material transportation consists of three parts: aggregate conveying, powder conveying and liquid conveying.

Aggregate transportation: At present, the aggregate conveying of the belt type concrete batching plant has two modes: hopper conveying and transmission belt conveying. The advantage of the hopper conveying is that the floor space is small and the structure is simple. The advantages of the belt conveyor are that the conveying distance is large, the efficiency is high, and the failure rate is low.

The belt conveyor is mainly suitable for the concrete batch plant with the aggregate temporary storage bin, which can improve the productivity of the concrete machinery.

Powder conveying: The powders available for concrete are mainly cement, fly ash and mineral powder.

At present, the commonly used powder conveying method is screw conveyor conveying, and the large mixing building is transported by pneumatic conveying and scraping. The advantages of spiral conveying are simple structure, low cost and reliable use. Liquid transport mainly refers to the transport of water and liquid admixtures.

4. Material storage system

The materials available for storage of concrete are basically the same, and there are aggregates for open storage (also for closed warehouses for large-scale commercial concrete mixing plant in cities); powders are stored in fully enclosed steel structure silos; and admixtures are stored in steel structures.

5. Control System

The batch plant machine control system is the central nerve of the complete set of equipment. The control system has different functions and configurations depending on user requirements and the size of the batching plant. In general, the small concrete batching plant control system available on the construction site is simpler, while the large concrete batching plant system is relatively complicated.