Performance characteristics of HZS60 stationary concrete bat

How many square concrete is poured per hour in HZS60 stationary concrete batching plant (60 square stationary concrete batching plant per hour)? HZS60 concrete batching plant can mix 60 square concrete per hour. This is the theoretical productivity. In the specific production, the output of HZS60 concrete batching plant can consult the staff of batching plant manufacturer.

The working cycle time of HZS60 stationary concrete batching plant is 60 seconds. It has no sewage discharge and noise pollution. It conforms to the EIA of concrete mixing plant. It has the advantages of less investment, strong mobility and small floor area. It also has the advantages of high production efficiency and strong working reliability of mixing building.

The use of 60 square concrete mixing station covers highway, high-speed railway, water conservancy, bridge, port, wharf, real estate, submarine tunnel, subway, artificial reclamation, infrastructure, commercial mixing and other key areas related to people's livelihood. _

The configuration of 60cuble concrete per hour machinery:

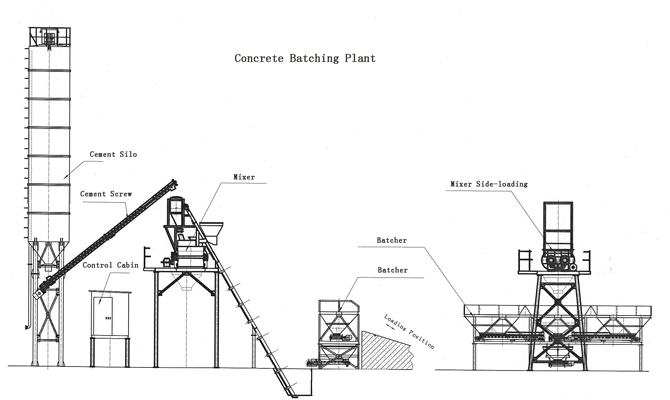

HZS60 stationary concrete batching plant is mainly equipped with a JS1000 concrete mixer, a PLD1600 four-storehouse batching machine, a set of cement weighing, a set of fly ash weighing, a set of water weighing, a set of additives weighing, a set of external additives mixing tank, a set of aggregate belt conveyor and intermediate storage warehouse, three LSY219-8M screw conveyors, two 100-ton cement warehouses, a 60-ton cement warehouse and a set of external additives. The air circuit system, a set of circuit system and a set of control system are composed.

The performance characteristics of China concrete batching plant are as follows:

1. The aggregate is measured separately through the proportioning machine and controlled by full-automatic computer. The operation is simple, easy to adjust and reliable.

2. The use of forced double horizontal shaft concrete mixer can mix a variety of concrete;.

3. The belt conveying feeding method has high productivity and is suitable for mass concrete production on site.

Previous advantages of traditional batching plant equipment:.

1. The double horizontal shaft forced concrete mixer with excellent performance is used as the matching main engine. The mixing speed is fast, the mixing range is wide and the concrete quality is high.

2. Equipped with touch screen, micro-computer, two operating systems, manual, semi-automatic, automatic three working modes. Ensure reliable operation of equipment. _

3. Using the patented point feeding technology to ensure the dynamic measurement accuracy of <1%. _

4. Use the pneumatic conveying device of the admixture measuring scale which has obtained the national patent to measure and convey the admixture, so as to avoid the concrete quality accident caused by the failure of the admixture system.

5. Unique proportion storage, automatic compensation for drop, water content of sand and stone, under-balance, alarm correction of overbalance, on-line modification of formula, data preservation, query, report printing and other functions.